Guest blog by Greg Auger, P. Eng, President of Millstream Engineering

As utilities across Canada work to modernize aging hydropower infrastructure, the demand for proven, locally supported mechanical solutions is rising. At Millstream Engineering, we’re proud to partner with Thordon Bearings, a Burlington-based manufacturer, to support Canadian utilities with grease-free, water-lubricated solutions that extend service life, reduce maintenance costs, and help eliminate cross-border supply chain risks.

Together, we supply a complete range of Canadian-made products for turbine upgrades and unit overhauls:

- Wicket gate bushings

- Operating ring wear pads

- Shaft seals

- Water-lubricated turbine guide bearings

- Filtration systems for shaft seal protection

These components are designed specifically for the rugged operating conditions of Canadian hydropower stations—offering enhanced performance, simplified maintenance, and secure local availability.

Supporting Hydropower Projects Across Ontario

Ontario’s hydropower fleet includes more than 220 generating stations—many of which are over 70 years old. As refurbishment programs accelerate, Thordon Bearings and Millstream Engineering have been trusted to support some of the province’s largest and most critical upgrade projects.

Chenaux Generating Station – Upgrading Shaft Seals

Originally built in 1950, the 144MW Chenaux Generating Station has eight identical vertical propeller turbines using conventional radial segmented shaft seals. Beginning in 2023 and continuing through 2024, Thordon upgraded all eight shaft seal assemblies to improve sealing performance and reduce leakage. The polymer-based SXL seals replaced traditional carbon-graphite seal faces, significantly extending service life while reducing maintenance intervals.

Otto Holden Generating Station – Supporting Turbine Overhaul Programs

Also located on the Ottawa River, the 243MW Otto Holden station is undergoing a mid-life refurbishment program targeting all eight units by 2029. So far, three units have been upgraded with:

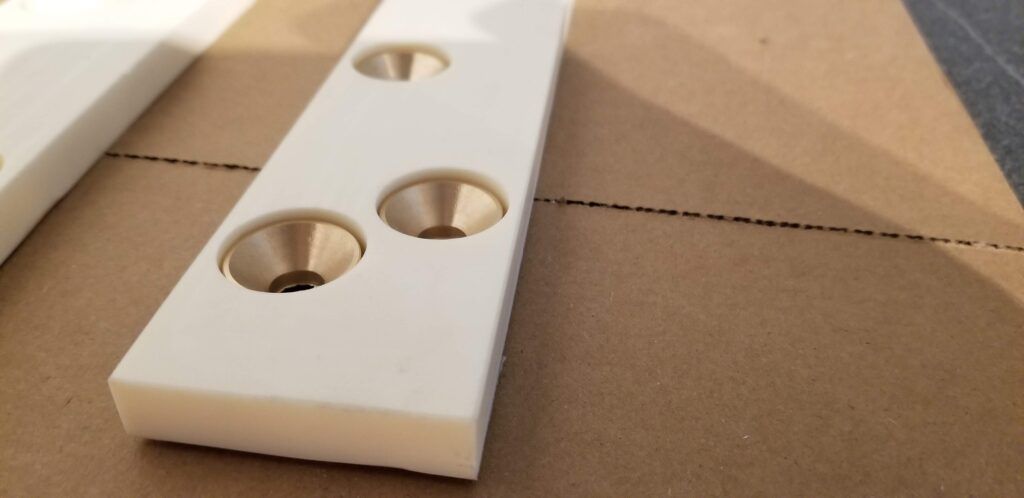

- 262 ThorPlas-Blue wicket gate bearings and seals

- SXL operating ring wear pads

- Thorseal wicket gate seals

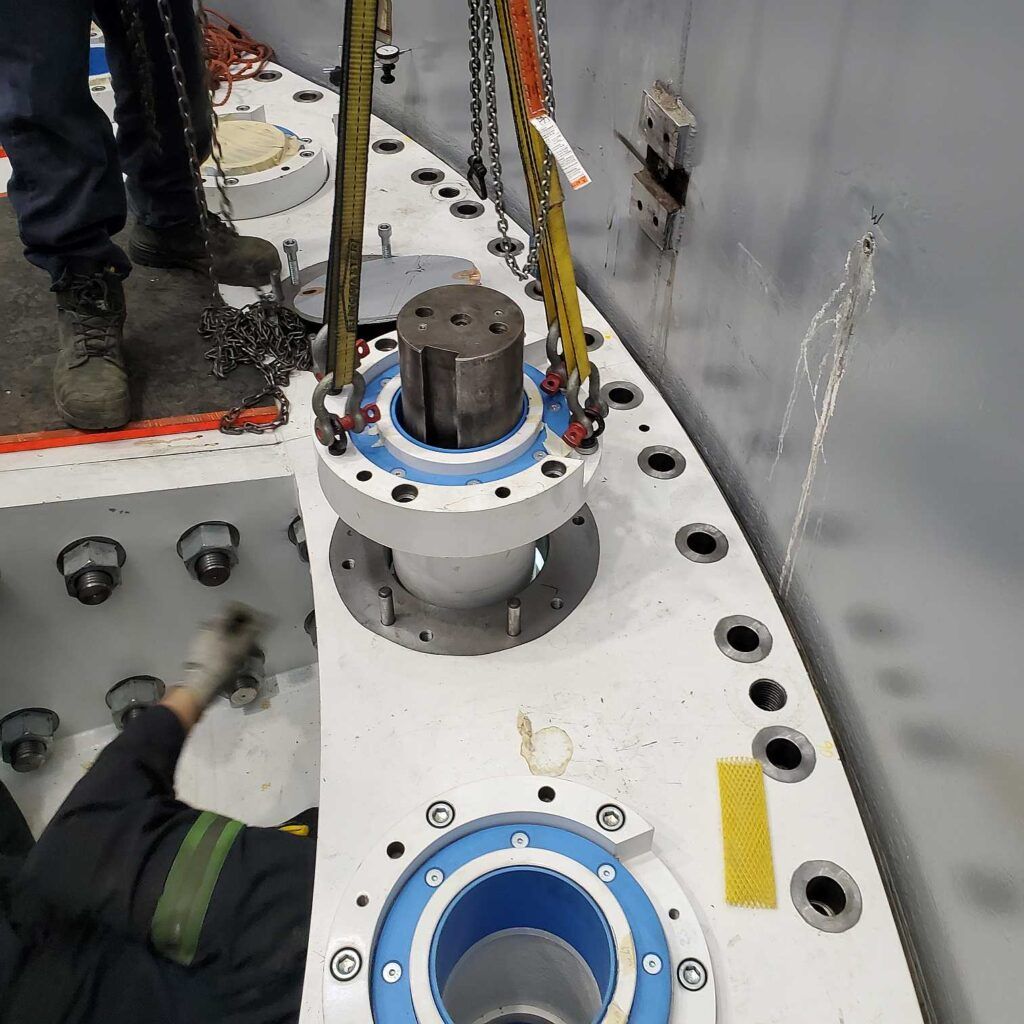

Lower Notch Generating Station – Outage Support with Fast Wear Pad Replacements

During a maintenance outage at the 274MW Lower Notch station on the Montreal River, existing operating ring wear pads were found to be damaged and worn. The customer turned to Millstream Engineering for a fast-track replacement.

The original phenolic-laminate pads had cracked at the bolted connection, so the replacement Thordon pads were designed with a strengthened fastener connection to reduce the risk of future problems. The gate lever thrust washers were also worn and replaced at the same time.

Millstream coordinated the supply and machining of rush replacement ThorPlas-Blue wicket gate thrust bearings and SXL operating ring wear pads, helping to avoid extended downtime and restore plant reliability.

Why Utilities Are Choosing Made-in-Canada Solutions

As utility teams plan for future overhauls, many are looking beyond traditional component replacement. There’s a growing push to specify long-life, grease-free alternatives that deliver better reliability and simplify plant operations.

Thordon’s polymer materials, ThorPlas-Blue and SXL, are engineered specifically for high-load, slow-speed hydro applications. Unlike bronze or phenolic bushings that require regular greasing, these materials are fully self-lubricating and wear-resistant—even in wet or contaminated conditions.

Millstream and Thordon also offer complete shaft seal systems, which can reduce leakage by up to 70% compared to carbon-graphite seals. With the addition of Thordon’s new seal-specific water filtration package, utilities can maintain clean lubrication water, extending seal and bearing life even further.

Local Support Makes the Difference

Beyond the components themselves, having local support for design reviews, budgeting, and technical troubleshooting has become a key priority for Canadian hydro teams. Millstream Engineering provides:

- Budgetary cost estimates for overhaul planning

- Feasibility reviews to confirm design fit and performance benefits

- Concept sketches to support internal project approvals

- Engineering documentation and installation guidance

As a Canadian company working hand-in-hand with a Canadian manufacturer, we can respond quickly—without the delays or unpredictability of international logistics or tariffs.

What’s on Your Project Horizon?

If you’re planning a turbine upgrade or long-term overhaul, now is the time to evaluate Canadian-made solutions that offer:

- Reliable performance

- Elimination of grease points

- Reduced maintenance costs

- Full engineering support

What bearing and sealing challenges are you facing in your upcoming projects—and how could locally supported solutions help solve them?

Let’s talk. Whether you need a single linkage bushing or a full shaft seal upgrade package, Millstream Engineering is here to help you improve the reliability of your units.

Author Bio

Greg Auger, P. Eng. is the President of Millstream Engineering, a Canadian company focused on improving equipment reliability and reducing maintenance costs in hydropower and industrial applications. With a background in mechanical engineering, Greg works closely with utilities across Canada to implement polymer bearing and sealing solutions tailored to the harsh conditions of hydroelectric power stations.